What is the SCS Process?

The SCS Process is a revolutionary new way of processing steel coils.

SCS material is very clean, extremely flat and comes dry with no oil on the surface.

How SCS works

All coils processed through the SCS machine pass through a set of high-torque tension levellers which ensure the material

is extremely flat.

At the heart of our coil-to-coil system is a brushing unit. The material passes through a series of engineered abrasive

rolls where rust and a controlled level of scale is removed. Water is used to cool and lubricate the rolls as well as wash

away the iron oxide which has been removed. The material is then air dried to produce a clean, flat and dry surface.

In cases where only shape correction is required, the brushing can be omitted from the run. This is generally the case

for coated and cold reduced coil.

The SCS Line

Smooth

Clean

Surface

The Results

CLEAN – FLAT – RUST RESISTANT – EXTREMELY ENVIRONMENTALLY FRIENDLY

Differences between SCS and Pickled & Oiled Material (P&O)

-

SCS has a considerably longer shelf life than P&O without the need to apply a protective layer of oil. In normal

indoor storage conditions, SCS will stay corrosion free for several months.

-

With the use of tension levellers, SCS material is much flatter than P&O.

-

The use of SCS material will improve the efficiency of many fabrication processes.

-

The process does not use any chemicals, acid or heat and thus is extremely environmentally friendly. Please

contact Servosteel to find out how you can Reduce Your Carbon Footprint

by simply switching to SCS.

Please browse the above tabs to see process specific benefits that SCS can bring over P&O and Hot Rolled

material.

By simply switching to SCS cleaned steel, many users can achieve vast efficiency improvements throughout their production

process.

Welding Benefits

Welding is improved thanks to SCS

Welding Tests Show Stronger Joints

Tests have shown that weld joints on steel which has been through the SCS system are significantly stronger than with Hot

Rolled (HR) and Hot Rolled Pickled & Oiled (HRPO)

steel. The SCS advantage comes from higher weld integrity. A certain amount of the weld arc's energy goes into burning off

the oil on

HRPO coil or sheets and the dirt and scale on HR material.

This introduces even more contaminants to a HR or HRPO surface that is

already fairly 'dirty' compared to SCS. The net results showed a reduction in the integrity of HRPO and HR welds compared to SCS

welds. User experience gained since the tests reinforces this finding.

Robotic and Spot Welding

Robotic welding and Spot welding also see significant advantages on SCS material. The extreme flatness of the SCS material enables

more accurate welding. SCS is currently being used by some fabricators to solve welding issues on parts that are welded after being

pressed and bent.

More Accurate Welding

Not only are weld joints stronger on SCS material, but the flatness of the material will ensure faster and more accurate welding.

Regardless of how good your welding operative or machine is, if they are not working with completely flat material, you

may experience some

weld deficiency. Current SCS users have seen a massive reduction in repairs to seam welds and scrapped parts as a result

of switching to SCS material from HR and HRPO.

Handling & Cleanliness Benefits

Some manual welders have said that the cleanliness of SCS material prevents sheet slippage they get with P&O and greatly reduces

weld fumes. With a very clean, smooth and oil free surface, SCS is considerably easier to handle and means your tools, machinery

and shop floor will be kept cleaner.

Health Benefits

SCS is a big help in minimising welding fumes. Replacing P&O with SCS eliminates surface oil that can be dangerous in two ways.

First, burning the oil itself generates toxins. Second, the excess fumes generated from burning oil creates an effective medium for

transporting fine particles of metals, electrodes, insulators and other materials that comprise the toxins from welding. Some

fabricators are now learning that they may have taken an important step toward safeguarding the health of their employees by

switching to SCS and eliminating hazardous fume emissions.

Contact Servosteel for a sample of SCS material to perform your own welding tests and experience these benefits first hand.

Welding Guidlines

Click on the link below to view the SCS welding guidlines to be sure to achieve the best performance with this material.

Cheaper Paint-Prep and Better Paint Adhesion

Salt spray corrosion testing of SCS panels produced an important result --

you can achieve extended

corrosion resistance using just a single stage water rinse paint-prep. That's BIG potential savings to manufacturers who

paint their parts. American users have reported six figure savings by reducing their paint preparation and painting process.

Money Saving

Cheaper paint preperation

-

Current SCS users have found they needed to replace their iron phosphate solution much less often because SCS is so

clean. In fact it is so clean that some users have reported that they only had to replace their iron-phosphate solution in

the wash tanks once in five months, compared to previously having to change the

solution every month when cleaning P&O parts.

-

Some users lowered their iron phosphate concentration from the 3% they used with P&O to just 1% with SCS, and their

paint performance has never been better.

-

With P&O sometimes you cannot avoid some oil or contaminants clinging to parts despite rinsing. This often causes a

"fisheye" blemish on the paint finish. This usually means stripping and re-painting the part. Switch to SCS could mean that

rework expense of this nature is virtually eliminated.

Fabricators and manufacturers using SCS are proving in practice what the laboratory showed in principle:

SCS can help you substantially reduce paint-prep without compromising on paint performance.

Testing

Salt spray testing

With

no pre-treatment, even clean hot rolled with high quality powder coat paint

will show significant creep after 200 hours exposure. The most common chemical stage is an iron phosphate and water solution.

SCS tests exposed four SCS panels that received

no phosphate at all - only a

water rinse prior to a single powder coat with a common, good quality polyester paint. At each inspection interval up through 288

hours, the SCS panels showed no noticeable paint creep. The next inspection interval at 384 hours finally showed significant creep,

but the SCS panels had already demonstrated 300 hours corrosion resistance using just a water rinse pre-treatment

(

see test results here). You simply cannot get

performance like that from P&O or hot rolled.

Recommendations

Parts ready to paint

Leading paint experts who have conducted the research suggested reducing an existing phosphate pre-treatment to a two-stage rinse:

-

The first stage should use a low-foaming surfactant at 0.1% concentration (by volume) in water as a recirculating stage.

Use a clean, overflowing water rinse at the second stage.

-

For very clean SCS (lighter gauge material), it may be feasible to use only the first stage and reduce the surfactant

concentration to 0.01% - enough to give the SCS low surface tension so paint 'wets out' evenly while curing.

The manufacturers who outsource painting because they lack pre-treatment systems may now consider painting SCS parts

in-house. Those with pre-treatment systems may reduce their paint-prep as noted above.

Dirt smudges, fingerprints, etc. obviously require some level of paint preparation, but you should be able to minimise your existing paint-prep

system when you switch to SCS. Testing for your individual process and paint system should be done to determine exactly what is necessary for

your application.

Paint-Prep Guidlines

Click on the link below to view the SCS paint-prep recommended guidelines and ensure you are running the most efficient

paint preperation process on SCS material.

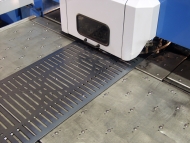

Laser Benefits

SCS is ideal for laser cutters

It is no secret that lasers love flat material. The SCS Process produces a surface with an extremely high degree of

flatness which is absolutely ideal for laser cutters.

Increase Laser Cutting Speed

-

The extreme flatness of the SCS material provides you with a very consistent distance between the lens and the

material surface. This allows you to choose the correct nozzle size and power level to enable you to operate your

laser at 100% cutting speed. For the best results download our

Laser Cutting Guidelines.

Corrosion Resistant Material

-

When we spoke to some laser cutters in the West Midlands, they told us that rust or corrosion was a major material

issue for them. Rusty sheets often have to be ground or discarded. The SCS steel has a fine layer of Wustite

(FeO) mechanically bonded to the surface which in turn acts as a protector against oxidation.

Stored in normal dry conditions, SCS material will stay rust free for many

months.

Significantly Reduced Springback

-

As part of the SCS process all coils go through a high torque tension leveller in order to produce the

ultimate flat surface. Once a coil has been SCS processed and has been correctly decoiled, there will be virtually no

spring back in the material either during or after laser cutting.

This will mean no head damage from spring back.

Edge Roughness

-

Tests conducted by Nottingham University found that the measured surface

roughness of the cut edges produced on

SCS steel were considerably less than that of other hot rolled and cold rolled material.

Surface Cleanliness

-

No Oil - The absence of oil on the SCS surface means there is no hazardous

smoke produced during cutting.

-

You will not experience any material loading problems from oiled blanks sticking

together - This is a benefit which all laser users will feel but a major advantage for lasers with automated

loading systems.

-

Material handling is made much easier, simpler and cleaner with the absence of

oil - The shop floor is cleaner, tools & machinery are cleaner and require less frequent wipe downs.

-

Simple savings on consumables (e.g. gloves, shoes) are also achieved by

switching to SCS.

Laser Guidlines

To help you achieve the best results on this material, please download and follow our Laser Cutting Guidelines.

Improve margins on low grade material with the Servosteel Coil Recovery Service

Opportunity to maximise your steel value

Servosteel, the UK's number 1 toll processor, brings you a way of recovering damaged or low

grade steel coils via the revolutionary Coil Recovery Service. Already many of our customers have returned degraded

steel coils back to their full potential by using the Coil Recovery Service. Our customers regularly see savings of £100 per tonne as they no longer have

to sell coils as secondary material. Take a look below at the types of material we can restore and see how you can

realise the full market value of your low grade stock.

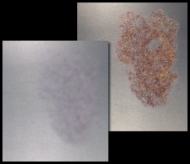

Before

After

The process of reclaiming your secondary coils

The use of roller levellers and a high degree of tension to the strip during the cleaning process produces an exceptional

degree of flatness. The brushing unit then removes any rust or scale that has built up on the surface.

Please have a look at our "Coil Conditioning" video to witness for yourself a downgraded coil being restored to its

former glory.

We have had great success reconditioning defective coils - full middle, bad edge shape, poor build up etc can all be

eliminated.

Water Damage

Heavy rust and corrosion can be completely removed from the surface. If you have coils that have degraded over time or

during transportation, the Coil Recovery Service can restore them to their former glory. Providing you with a clean, dry and rust resistant

surface, the line can bring secondary coils back to caption.

Shape

Whether your coil has Edge Wave, Full Middle, or a Bow, the Coil Recovery Service can correct shape issues to significantly increase the value

and workability of your coil. The Coil Recovery Service uses a high torque tension leveller to achieve exceptional flatness.

Quality issues such as coils outside flatness specifications can be resolved with the option of surface

cleaning. The majority of strip mill products can be processed through the line.

Click the 'Shape Correction' video to see a coil with extremely bad shape transformed into a smooth, clean and extremely

flat strip of steel. The shape in this particular coil made it unworkable and would have otherwise been moved on as

scrap.

Coil Break is improved with the

Coil Recovery Service

Coil Breaks

Coil break happens when localised yielding occurs during the uncoiling or recoiling of the hot strip. With the use of a

tension leveller to achieve exceptional flatness, a side effect is that coil breaks are significantly improved on hot

rolled coils. Breaks will be improved both visually and to the touch.

A better product all round

Not only can the Coil Recovery line be used for restoring low grade coil, but once a coil has been subjected to the Coil Recovery Service

it brings many advantages to a range of production techniques.

Browse the tabs across the top of the page to see specific advantages for different processes.

Future processes to consider

-

Processes that compress or deform the steel sufficiently to disrupt the surface oxide layer.

-

Hydroforming, cold reduction, deep draw and deep draw with spinning, may need

a different dry lubricant and process adaptation for recovered material to work well.

-

Porcelain enamel coating and electrolytic planting.

-

Surface sensitive material when utilising the brush cleaning system.

For more information on the benefits the Coil Recovery Service can bring to your production process, please contact our Operations Director

Phill Guest on 01384 471371 or e-mail

pguest@servosteel.com.

Multi Process Benefits

Steel fabricators with multiple processes under the same roof have witnessed significant efficiency increases on a range

of machines.

Laser Cut/Punch ⇒ Press Brake ⇒ Weld ⇒ Paint

Each stage will see valuable improvements with SCS processed material

Punch & Press Benefits

It is no secret that both punch and press machines work best on flat material. SCS material is significantly flatter than

P&O and HR material. Your machine will be able to perform more efficiently

producing

less scrap or unusable parts.

Not only does the SCS Process provide flatter material, is also significantly reduces the possibility of spring-back in

steel sheets. Current users have solved issues with spring-back both on Laser Cutters and on Punches by simply switching

over to SCS material.

Manual Press Brakes

Automated press

Where operators are manually handling the material going onto a Press-Brake, slippery oiled surfaces are potentially dangerous

and difficult to handle. The oil on P&O material has been around for so long that most people cannot imagine working

without that burden. However:

-

Imagine handling material that is extremely flat but at the same time very clean and completely dry with no oil.

-

Imagine a clean shop floor without the annoying dirt and oil everywhere.

-

Imagine the savings on consumables with employees using things like the same gloves for longer periods.

-

Imagine not having to wipe the oil from machinery.

SCS brings these benefits to all fabricators and –

AT NO EXTRA COST!

It is no wonder our American friends have described it as

‘The Fabricators

Dream’

Current Users

Often users have switched to SCS to solve a shape problem on one machine and ALSO noticed significant improvements on another.

For example, a current steel fabricator using SCS is producing a part that is pressed awkwardly

through multiple angles so they switched to SCS as the material had to be extremely flat. Real value was noticed when they welded this part

onto another using a robotic welder. P&O sheets weren’t exceptionally flat therefore caused the robotic welder to

often produce inadequate welds. This required time consuming manual re-welding or the part had to often be scrapped.

SCS has not only solved the issue on the Press-Brake, but also brought great benefits and savings to the company

through their welding process.

Rust resistant SCS

Rust Resistance

Stored in normal indoor storage conditions, SCS will not rust for several months. This gives fabricators great flexibility

with both sourcing and storage of material and semi-finished parts.

Nottingham University have carried out tests on SCS which proved that with the

micron thin, clean protective layer of Wustite on the surface, it is harder to scratch the surface of SCS material and

cause surface corrosion. SCS parts will not rust after being handled like P&O material.

Browse the above tabs to discover more detail about how Steel Fabricators can realise the SCS benefits on various

different processes and machines.

SCS Line

SCS is hot rolled black material which has been taken through an environmentally friendly process using engineered abrasive rolls and water to produce a 'wipe clean', smooth, rust resistant surface.

The process does not use any chemicals, acids or heat. Just water.

Machine Specifications

| Width |

Thickness |

I/D |

O/D |

Weight |

I/D |

O/D |

| Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Max |

Size 1 |

Size 2 |

Max |

| |

|

|

|

|

|

|

|

|

|

|

|

| 600 |

1830 |

1 |

8 |

483 |

965 |

1200 |

2000 |

30 |

508 |

600 |

2000 |

Please note: All combinations may not be available and can be dependant upon material specification to be processed. Thickness' as low as 0.4mm have been successfully tension levelled reducing and removing significant shape problems. This process is not suitable for previously slit material.

Adobe Flash Player 6 or above is required to view this animation.